G7- Compliant packaging not only helps the printing companies control product quality during the printing process but also provides standardized and high-class packaging products to customers.

What is G7 printing and what does it mean, let Vietnam Packaging provide some basic notions in this article.

What is the G7-compliant packaging?

A packaging that meets the G7 printing standard is the type of packaging created by the calibration method with G7, in which G7 is the calibration method controlling the printing process. This method uses two curves of neutral density. One curve for black and one for combined CMY gray to adjust the CMYK image to a neutral gray balance.

Generally, the G7 provides a simple process for measuring sheets and making decisions to control problems that occurred during packaging printing.

“G” stands for Gray and “7” stands for the 7 colors of ISO CMYK and RGB. The G7 method is known as the gray balance approach for the proofing and actual print applied in printing techniques.

.jpg)

The main content of the G7 printing standard

The packaging that meets the G7 printing standard is used for the proofing and actual printing system. The G7 uses “chroma” data to achieve the gray balance that conforms to the ISO 10128:2009 neutral density printing standard. The main content includes:

- Methods to achieve G7 gray balance.

- Continuously monitor the measurement value of the combined 3 components of CMY as neutral gray rather than each CMY color separately.

G7 printing calibration helps control gray tones from 0% to 100%. It also adjusts the curve of the 3 components CMY and black K, aiming to conform to G7 specifications, leading to consistent prints from proof to print. The devices must only be operated within the tolerances allowed by G7.

The G7 method is applied to many packaging printing technologies such as offset, flexographic, digital printing, silkscreen printing, etc. They are used for all types of inks and printing materials, even those that are not included in ISO standards.

>>> FSC chain of custody and sustainable packaging solutions

Benefits of businesses when using G7- compliant packaging

Printing G7-compliant packaging is important to businesses, bringing the below benefits:

- G7-compliant packaging for a beautiful and unified quality

- Saving time and costs

The control method and the G7 require all devices during the printing process to be synchronized. Therefore, all prints from proofing to actual printing will provide quality images with unified and beautiful colors, avoid errors between proofing and actual prints. This shows the professionalism of the enterprise in production and business activities.

The G7 method uses a variety of printing techniques and materials, thereby helping to speed up the printing process and limit errors for finished prints. Based on the G7 printing standard, printing is fast and convenient, helping to reduce production costs.

.jpg)

- Clear brand identity

- Help customer avoid confusion

According to G7 standards, the products are made almost identical with each other within the allowed tolerance. Therefore, the packaging samples will be unified in color. Color is a clear sign of brand identity. This uniformity helps increase the ability of customers to identify and remember the brand.

This is extremely important and necessary for any product, especially those that are newly launched in the market. Along with the information on the packaging, the uniformity of color helps customers easily identify the products of your company, making your product easier to distinguish in the proliferation of fake ones. Also, it helps limit the confusion of customers that affects the reputation and brand of the business.

>>> How to print the high quality cosmetic box packaging in Vietnam?

Important notes when ordering G7-compliant packaging

This certificate is only valid for 1 year and is renewed annually. To obtain this certification, a packaging printing company that meets G7 needs to pass the G7 assessment process with the support of G7 experts. Professionals are required to pass comprehensive G7 exams every 2 years.

G7- compliant packaging is provided by G7- certified packaging company. The G7 company was granted a G7 certificate by IDEAlliance when the equipment and systems were successfully calibrated to G7.

With many benefits to businesses, packaging that meets G7 printing standards has become very popular today. When ordering this packaging template, in addition to factors such as price, design, or material, you need to pay attention to the printing company. To have the finished product as you want, choose a reputable company that has been granted the G7 certificate following regulations.

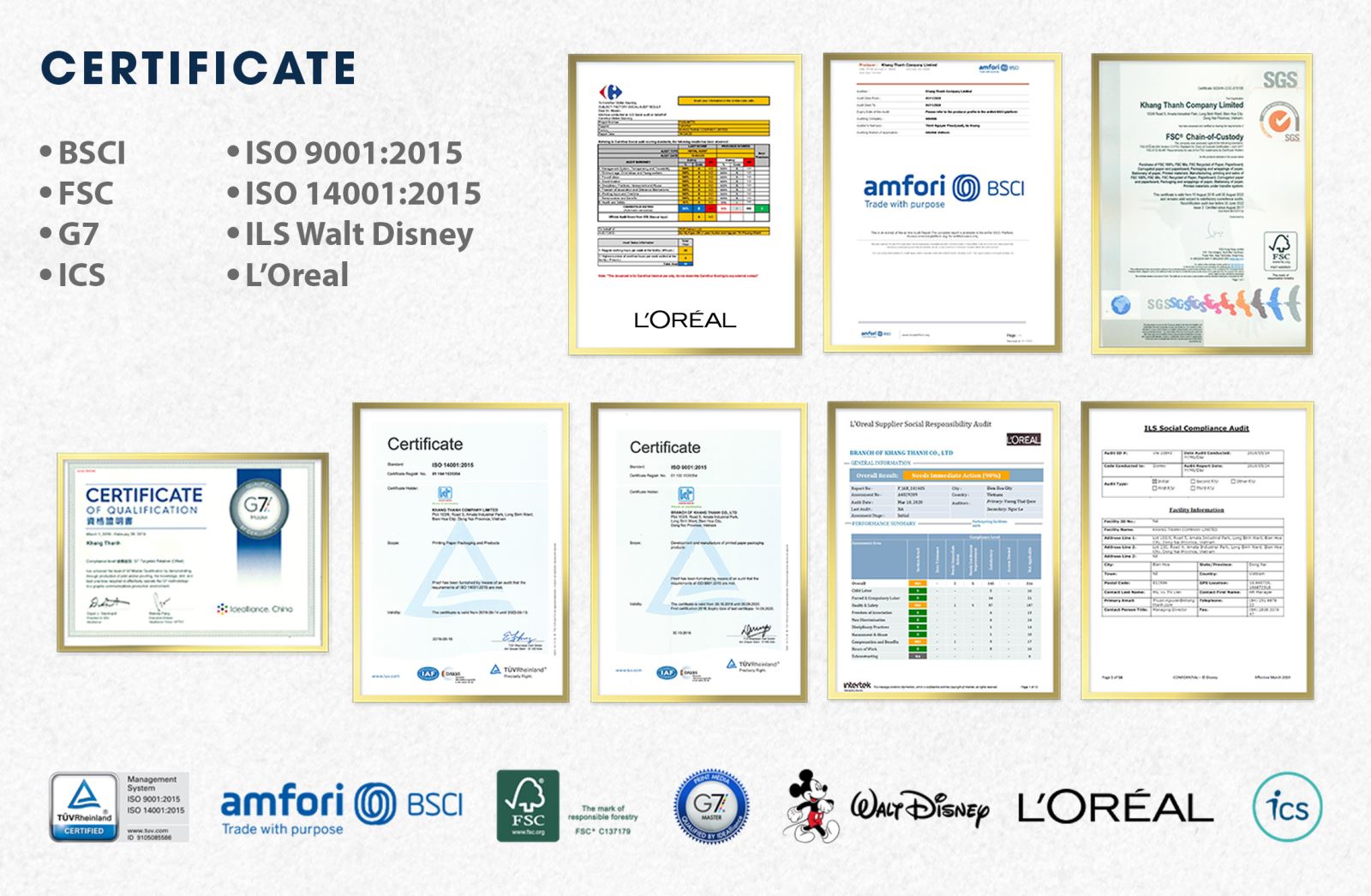

At Vietnam Packaging, we constantly strive to create standard printed packaging products. In addition to quality certification such as ISO 9001: 2015, FSC, G7 is one of the important bases for Khang Thanh to bring quality packaging printing products to customers.

.jpg)

>>> Why joining BSCI is presenting social responsibility?

Let us help you solve your problems with safe and premium packaging solutions:

KHANG THANH PACKAGING COMPANY – HOUSE OF PACKAGING

Tel: 077 8878 222

Email: info@khangthanh.com