There are more than 2 million farms across the US and the average consumption there is 123 kgs per capita yearly. From that number, it is easy to see the importance of produce delivery in an attempt to preserve freshness, quality, and taste while being transported to grocery store shelves.

Surprisingly, more than half of the fruits are spoiled during the production process, post-harvest treatment procedures, or in storage and transportation. This truth once again highlights the paramount importance of proper fruit packaging.

Farm owners should invest more time in finding the right packaging manufacturer or supplier for their products. In that way, their business will ensure short and long-term sustainability goals.

The ideal fruit packaging options

It is essential to pair up the right produce packaging with correlating agricultural goods. Each type of fruit needs a different way of packaging handling, resulting in diverse types of packaging to ensure they arrive ready to purchase and consume.

Superior fruit packaging often includes common traits as follows:

- Adequate ventilation to allow heat from respiration to escape and ensure the mild temperature for the content.

- Preventing produce water loss

- Detering the content from possible injuries during transit and handling

As fruit packaging must contain proper elements to prevent its contents from being spoiled, it is comprehensible that carton packaging comes in handy and accounts for 66% of the food-related segments, specifically produce.

Read more: Time To Reevaluate Shelf-Ready Packaging – Retail Ready Packaging

Fruit packaging solutions

Apples require a different style of packaging than watermelon, coconut, and the like. It means that each fruit needs a specific kind of packaging to ensure the wholeness of the contents.

The right packaging option for your produce must be high-quality for the shipment and retail process, cost-effective, and good for long-term branding, whether that means case and carton packaging, flexible or retail-ready designs.

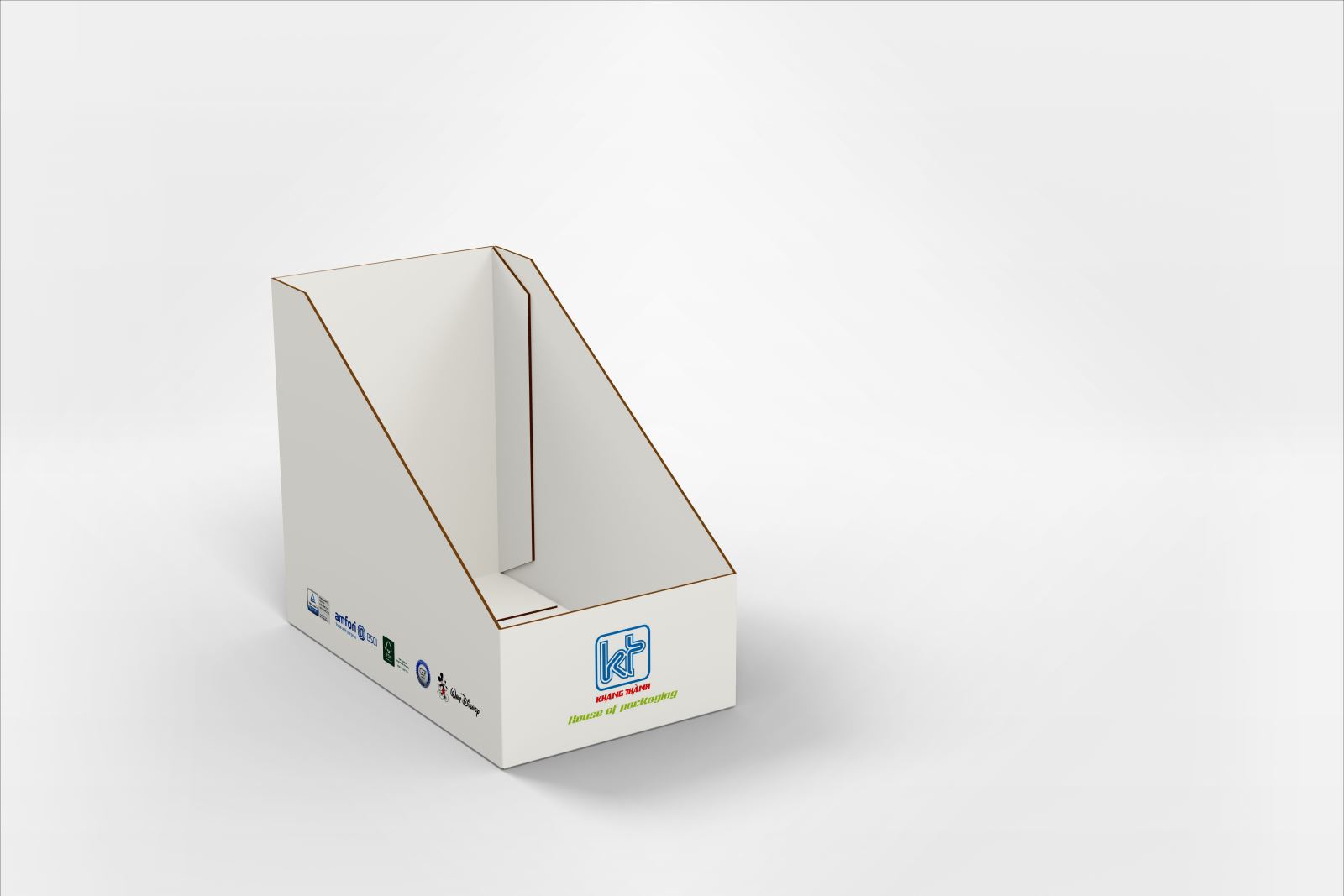

Corrugated fruit packaging – A noteworthy option

Corrugated fruit packaging is inarguably the best choice for the wide array of the most popular and safest packaging solution for produce. Box, tray, and carton are used only once and recycled to keep cross-contamination at bay.

This powerful property helps farmers, retailers, and consumers have optimum hygienic conditions. The single-use packaging is effective in preventing produce from widespread decay.

For example, an outbreak of the destructive banana disease Fusarium wilt TR4 in Asia and Australia led the United Nations Food and Agriculture Organization to urge countries to be vigilant and take measures to prevent further contamination.

The best way to stop that bad crisis was to prevent it from continually spreading. Besides, corrugated boxes are versatile and can be formed in all shapes and sizes leading to reduce product damage during transportation, warehousing, and transfer to shelves.

On top of that, this kind of packaging receives huge attention for being retail ready which helps brand lower labor cost and clearly present key branding messages.

Hard vs. Flexible fruit packaging

Clamshell fruit packaging

A clamshell is a one-piece container consisting of two halves joined by a hinge area which allows the structure to come together to close. Clamshells are often made of shaped plastic material, in a way that is similar to a blister pack. The name of the clamshell is taken from the shell of a clam, which it resembles both in form and function.

Flexible fruit packaging

Flexible packages can take a variety of physical forms. Wraps consist of a layer of material surrounding the product or products and can be classified as intimate wraps, which make direct contact with the product, or as bundling wraps, used to join together two or more products so they can be handled as a single unit.

Clamshell packaging and flexible packaging are frequently chosen to pack fruits which can let the contents breathe through proliferation holes. They can be used to neatly present small and juicy berries such as blueberries, cherry tomatoes, and grapes on shelves. Three types of fruit packaging that provide this ventilation style include:

- Closed packaging no hole– made with a thin film that allows gasses to slowly seep through by disintegration

- Micro-perforated packaging – flexible packaging that allows carbon dioxide, water vapors, and oxygen to pass through

- Macro-perforated packaging- clamshell packaging with large holes or slits for ventilation

Choosing the right type of hard or flexible fruit packaging material will ensure your produce remains fresh and retail-ready. Packaging assembly should also be taken into careful consideration when selecting packaging material, type, and adhesives.

roper packaging and temperatures can do wonder in “delaying” the ripening process of fruits, which gives retail units more time to place them on shelves and enhance product longevity. Having the correct produce packaging will ensure your products last longer and arrive at their destination in optimal condition.

At Khang Thanh, we specialize in providing fruit packaging: cardboard and paper boxes, paper trays, display ect. to pack all types of fruits. Contact us to get a detailed quotation and latest promotion programs.

KHANG THANH CO., LTD – HOUSE OF PACKAGING

Tel: (+84) 77 8878 222

Email: info@khangthanh.com