Counterfieting is becoming increasingly sophisticated in almost all items – from food, drinks, construction materials to fashion products, medicines, cosmetics. To distinguish authentic and fake goods, buyers can check the barcode printed on the product packaging.

1. What is the Barcode on product packaging?

All goods and products need to have barcode printed on their packagings. Barcodes are their “identity cards”, to help buyers distinguish quickly and accurately different types of goods.

A barcode is one of the identification technologies that automatically collects data from products, services, organizations, or locations – based on assigning a code (or number) to each object. Those codes will be in the form of alternating parallel gaps, arranged in a certain coding rule so that the scanner device can read them.

.jpg)

2. How to check barcodes by smartphone applications

It is simple to use an application to check barcodes. Use the camera on your phone to scan barcodes or the QR Code on the packaging or product sticker. The application will display all information that the business has provided, such as:

- Full product name

- Product type (color, color code, product code)

- Company name, brand

- Place of manufacture, manufacturing company address, country

- Product description

- E-commerce sites that sell products

- Demo image of the product

- Ingredients

- Manufacture date, expiry date

3. Recommended softwares to scan barcodes

- iCheck:

Constantly updated prices, information about the manufacturer, production address, contact phone number, reviews of other users about the product.

- Barcode Viet:

Scan barcode, QR code super fast even on low-quality cameras. This app displays most types of barcodes in Vietnam: display manufacturer information, contacts, contact phone number, product update date.

- QR Barcode Scanner TeaCapps

The application can scan all popular barcode formats such as QR, Data Matrix, Aztec, UPC, EAN, Code 39.

Read more: 7 Step Process To Order Premium Paper Bags In Vietnam

.jpg)

4. Does barcode scanning software verify authentic goods?

The barcode on packaging should be used to check and compare the accuracy of the information on the product packaging when buyers are in doubt.

In addition to the bar code, we need to pay attention to other factors such as checking invoices, receipts, anti-counterfeit labels, product form, logos, packaging – all must be clear and detailed.

.jpg)

5. What to notice when scanning barcode on packaging?

There are many reasons why the barcode on packaging cannot be scanned, they may be corrupted or simply printed on materials that are not up to standard quality.

– Code readers are not compatible with barcodes

There are many types of barcodes on the packaging, each will have a corresponding barcode, because the encoding is different, so the size and shape cannot be the same.

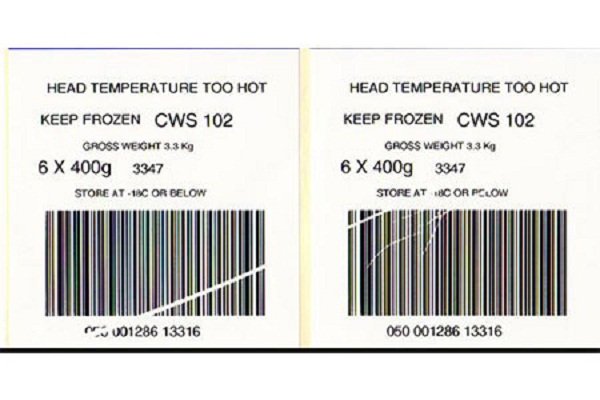

– Barcode printing error

Most bar codes on products are printed by the manufacturer. Each manufacturer prints the code on a different packaging material even the color of the barcode is different. Others print where there is no flat surface, which makes reading them more difficult.

– Barcode color errors

The color of the barcode also greatly affects whether the code can be read or not, the scanner can only read the bar code when dark bars are used on a light background, in contrast to the printed barcode.

.png)

– Barcode position is not correct

Check if your bar code is at the corner or the edge of the product packaging, whether it is hidden or not.

– Barcode printed product surface

If the product has a transparent or translucent color, this will cause problems with color contrast.

.jpg)

– Barcodes are blurred or broken

Check if all barcode lines are clear and clear. redundant ink points, broken, if a barcode scanner will be difficult to read in this case.

– Barcode length does not match

A fairly common mistake during print design. If you notice you may recognize barcodes that can vary in length. The barcode length here is the width of the barcode, it may be too long or too short.

In addition, the process of transporting the product may cause the barcode label to peel, scratch, or fade. Ensure the barcode is always stable when shipping. In particular, some barcode labels are very sensitive to the environment, so pay attention to the use of paper label materials or product packaging when printing bar codes.

.jpg)

Read more: 8 Basic Steps In Vietnam Packaging Company’s Manufacturing Process

6. What is the real meaning of barcode on product packaging?

The barcode we usually see on the package consists of two parts:

- Codes of goods for people to identify

- Barcodes for computers and scanners are included in the system management

– Barcodes on packaging have 2 common standards: UPC-A and EAN

- The UPC-A standard is a 100% American product: this standard is specific to the Canadian and US markets

- EAN: used for markets in Europe, Asia and many other countries

You can refer to bar code printing and usage regulations at the GS1 Vietnam website.

In Vietnam, most goods on the market apply EAN standard with 13 numbers, divided into 4 groups:

Group 1: From left to right, the first three digits are the country code (territory)

Group 2: Next with four digits is the enterprise code

Group 3: Next with 5 digits is the goods code

Group 4: The last digit (right) is the check digits

.jpg)

CONTACT US:

Khang Thanh – The packaging company in Vietnam specializes in producing paper bags, rigid box, labels, hangtag, books, calendar, POSM and so on. Contact us to support your brand with the right packaging:

KHANG THANH CO., LTD – HOUSE OF PACKAGING

Tel: (+84) 77 8878 222

Email: info@khangthanh.com