In the process of transportation, the method of the use of the corrugated box is an optimal choice with the aim to assure product quality that helps them be well preserved, undamaged, and deformed.

Besides, the types of carton packaging, like a corrugated box, are used by many businesses to build the product image that contributes to protecting the surrounding environment via the recycling process.

Nowadays, there are various kinds of corrugated boxes on the market, so it is hard to make a decision that is suitable for your products with good quality. Which are the criteria for product packaging for companies to select?

Cartons with the firm structure are 3, 5, 7 layers of a corrugated box

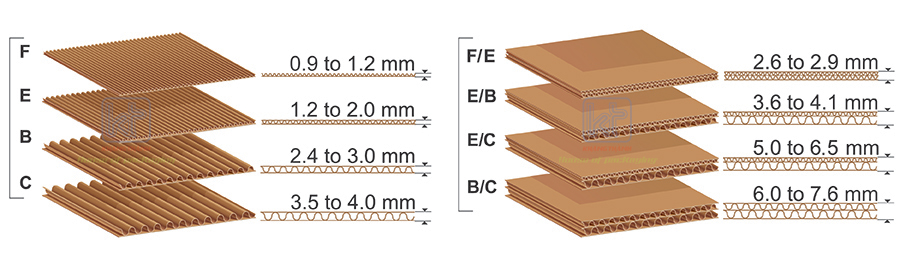

A corrugated box usually has two main parts: lining and intermediate layer. In particular, the liner is on the outer surface with the high endurance of strength, cutting, and water… The intermediate layer is carton paper in the form of a sine wave, known as corrugated form, which significantly reduces the damage of impact.

The standard quality of a corrugated box is a type of carton which is manufactured according to the rigorous process and technical requirements, with a firm structure of 3, 5, or 7 layers depending on product characteristics.

- The 3-layer carton box is made from a single-corrugated sheet shaped in the middle and two surface paper layers. Currently, this type accounts for over 90% of all carton boxes which are manufactured in the market.

- The 5-layer carton box made of the double corrugated sheet has 5 layers, including two surface paper layers, two corrugated layers, and one layer of paper in the middle. The 5-layer cartons are usually used for the export of quite heavy products.

- The 7-layer carton box comprises of three layers of corrugated shapes and 4 layers of flat paper. This type is merely used for the transport of really heavy goods.

See also: The characteristics of cardboard boxes in the packaging industry

The bulkhead, handheld corrugated box easy to arrange and store

The good quality of a corrugated box is shown through the design which is proper for product preservation. Besides, it also needs a convenient design in order to limit the damage to transportation.

Today, several types of corrugated boxes which are specialized in packaging specific products have the bulkhead so that you can save carton area and reduce the cost of packaging and shipping in the best way. It means that a large box will be divided into much smaller spaces that are more suitable for products.

Moreover, the partitions help prevent the collision of fragile products such as glass mugs, wine bottles, pottery, porcelain, and egg containers. In addition, they also reduce pressure on boxes by separating products from each other to protect them more safely.

If corrugated boxes designed with handhelds, they will support the transport process of products effectively. This is also a wonderful design with the aim to increase the advantages of product packaging.

.jpg)

Therefore, the kind of efficient packaging is the corrugated box with convenient design for storage and arrangement. In the process of transport, the goods need to go through the loading, unloading, and then storage in many different units. The shape of carton packaging is square and rectangular blocks that will make this process easier.

In the form of boxes, the product will be arranged in a certain number which is just enough with the inner space of the carton box. When arranging carton packaging together by stacking them systematically, it will help save space and make maximum use of the available space.

See more: 5 types of the most popular lids in carton box

Waterproof and moisture-proof corrugated boxes

In addition, to evaluate the base of structure and design, the preservation criteria of the corrugated box packaging are also thought a top priority. In particular, the waterproofing, moisture resistance of the product is increasingly concerned by many manufacturers.

Normal carton packaging products are able to absorb moisture quite quickly. The quality of goods will be seriously affected in cases of moldy environments with high air humidity. Therefore, the methods of enhancing the waterproofing of carton packaging play a crucial role in the preservation process.

The type of carton packaging which is appreciated by a lot of customers is a perfect packaging with the effectively waterproof, anti-moisture, and long-lasting abilities in the humid environment more than other materials.

See more: The top 5 printing technique for impressive paper box

.jpg)

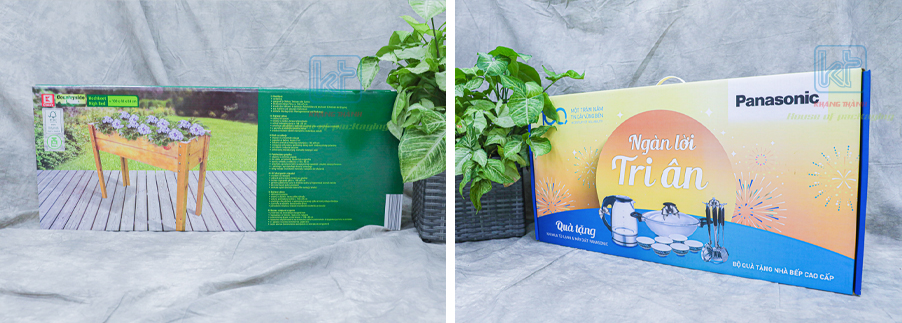

Offset printing corrugated box aims to promote the brand

Packaging in the corrugated box has the function of not only preserving products but also promoting brands and products to consumers.

To motivate customers to purchase products, businesses need to make a good impression on customers at first sight. Therefore, good packaging is a means that helps promote the product brand effectively via designs printed on the packaging. Great corrugated boxes should be appropriately printed design.

Offset printed corrugated packaging will create prominent products with beautiful, sharp, and lively image quality that can have a long service life and appeal to customers because of its excellent capability of advertising and marketing.

The information and relevant images of your brand should be printed exquisitely under a particular layout in order to make a perfect corrugated box product.

Khang Thanh – The packaging manufacturer in Vietnam specializes in producing paper bags, carton box, carton offset, labels, hangtag, books, calendar, POSM and so on. Contact us to support your brand with the right packaging:

KHANG THANH CO., LTD – HOUSE OF PACKAGING

Tel: (+84) 77 8878 222

Email: info@khangthanh.com